PYRGOS/MAVRORAKI COPPER METALLURGY I

- Chalcolithic to Middle Bronze II. from mine to mould

- The Metalsmith Tomb n.21

by

Maria Rosaria Belgiorno

Livio Pontieri

Cyprus' copper wealth and high quality minerals led to its identification as the Roman term cuprum (Kypros). However, evidence of copper processing is scarce before the Chalcolithic- Early Bronze age, therefore, the documentation presented in Scripta Cypria III sheds new light on the beginning of Cypriot metallurgy, which was a fundamental element in the evolution of maritime trade on the island.

Other contemporary metallurgical sites in the Mediterranean, including Cyprus, are equally rich in copper but do not have the level of productive continuity of Pyrgos/Mavroraki, as according to the 14C the Pre-Ceramic Neolithic site continued to be inhabited until the end of the Middle Bronze age, when it was destroyed by an earthquake.

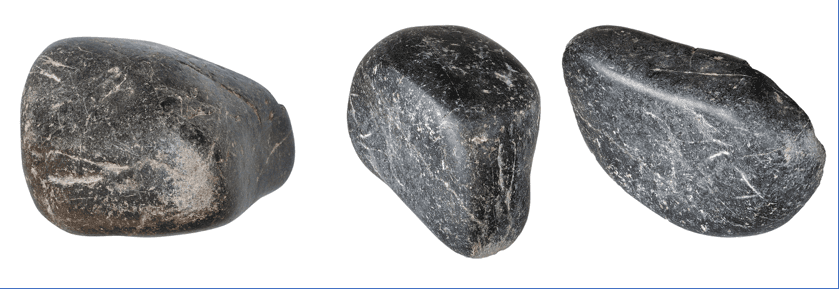

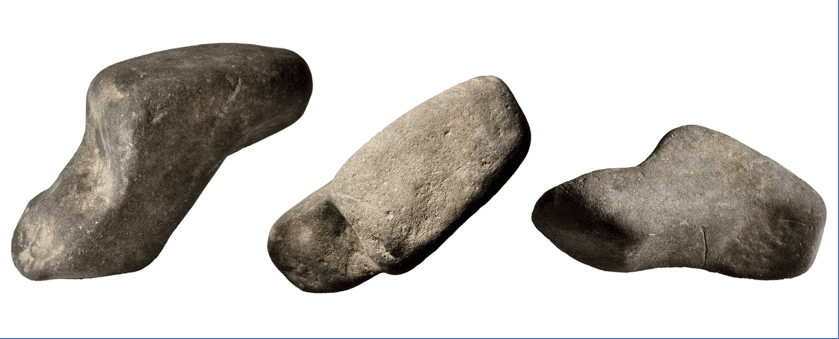

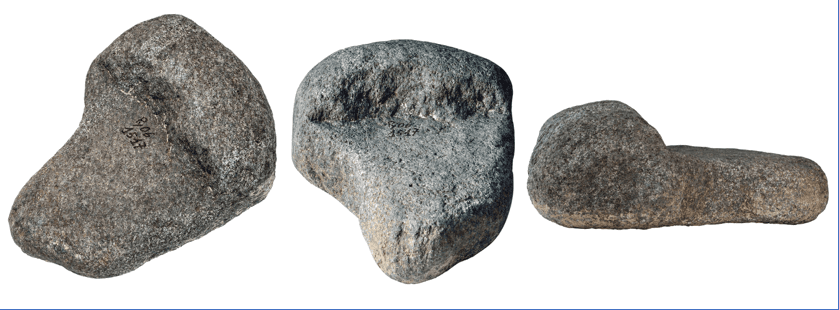

The materials that identify Pyrgos/Mavroraki as a copper worker community represent all the production phases, from copper extraction to the finishing of the artefacts, in a 4000-year time span of technology evolution. Alongside the few copper objects that survived to the earthquake, complete processing plants, infrastructure, stone tools, slags and processing waste of various kinds have been found in different occupancy levels that were not continuously used in metallurgy.

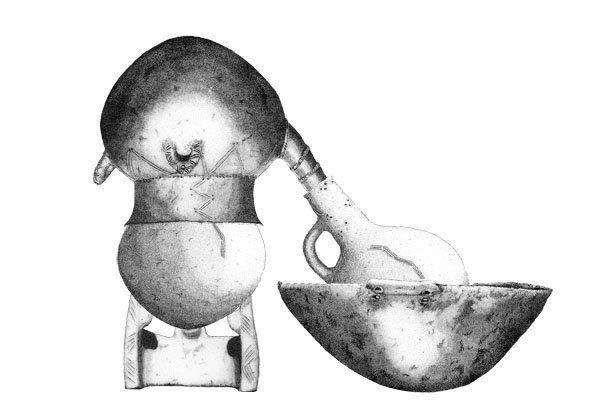

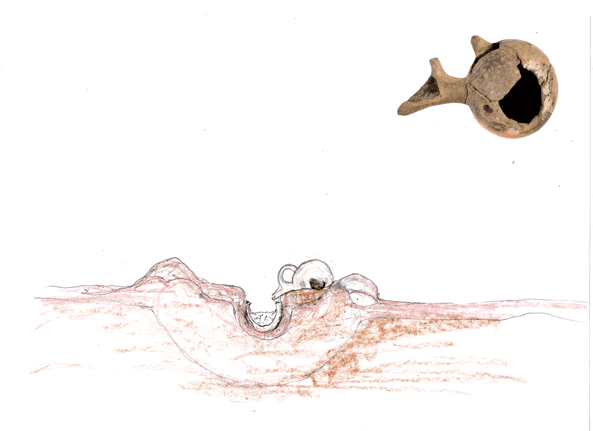

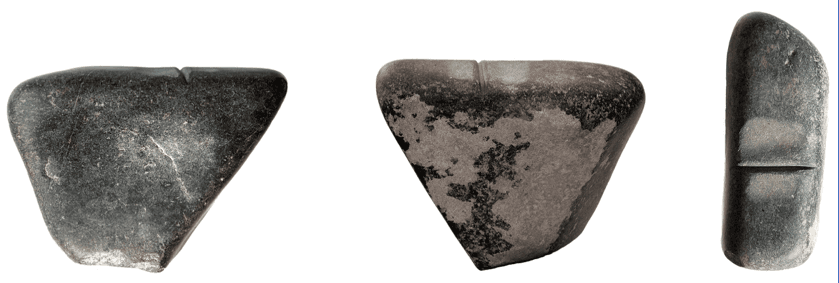

Alongside the working points, the fragments of crucibles and moulds, nozzles, bellows supports, and a vast lithic apparatus, including shaped anvils and mining tools for extracting minerals that shed new light on the ancient techniques have been found. Currently Pyrgos/Mavroraki seems to be the only settlement directly insisting on rocks containing copper oxides and sulphides which suggests a continuity of human habitation from the Preceramic Neolithic to the Middle Bronze Age.

However, the slags of Pyrgos/Mavroraki offer many additional data about the Mediterranean copper production from the Chalcolithic until the Middle Bronze age, encompassing the most important period of the birth and evolution of metallurgy.

The presence of slags until the bedrock made it necessary to carry out 14C dating of the charcoal taken from within the slags which gave four different calibrated datations: 8631-8291 BC, 4229-3960 BC, 2201-1948 BC, and 1937-1738 BC, demonstrating the ininterrupted activity of the site in copper processing.

Tomb 21 of Pyrgos, with its rich equipment, is one of the few European Early-Middle Bronze age metalsmith tombs, perfectly fitting into the industrial context with its repertoire of 13 bronzes and stone tools beyond any comparison in terms of size.

The existence of this ancient copper mining and processing site in Cyprus is of historical significance, as it testify that the island has been perfectly capable of cultivating its deposits of minerals and extracting the metals since the beginning of the Chalcolithic period.